Ariterm

- BioComp Boilers

- Arimax Bio Boilers

- Pellet Feeding Systems

- Fuel Storage Systems

- Biomass Burners

- Residential Boilers

Ekogen

Naarva

WTS

Bioenergy Equipment

Ariterm Group

Ventek is the exclusive distributor for the Ariterm Group in Canada.

Ariterm is a Finnish Company with locations in Saarijävi Finland and Kalmar Sweden.

The company was established in 1904 and has grown to be the leader of biomass boilers and components in Scandinavia. The Saarijävi factory is comprised of a 10,000m² production and assembly facility with state of the art robotics on 20 individual assembly lines and an 8,000m² warehouse facility for parts, components and finished products.

All products are certified to ISO 9001 and ISO 14001 standards. For the North American market, the pressure vessels are available with the ASME H stamp certification

Boiler sizes range from 40 to 3,000 kW and come in a variety of models and burners specific to the fuel type.

ARITERM BioComp Boilers 60–300 kW

The BioComp Boilers come in sizes 60 to 300 kW. The boilers are fully automatic and have a round vertical fire chamber and convection section increasing heat recovery and efficiency. The BioComp model is suitable for both wood pellets and chips.

Standard Features

- Automatic convection cleaning

- Plate heat exchanger and pump for domestic hot water

- Variable speed flue gas fan to maintain fire box pressure and even burns

- Large, ceramic insulated ash compartment which reduces radiation losses and discharge intervals.

- Burners can be mounted either side and are chosen for individual fuel types and specifications.

- Residual oxygen control

- Automatic ash removal

- Automatic back burn protection

For more information about ARITERM BioComp Boilers 60–300 kW

![]() ARITERM BioComp Boilers 40-300 kW

(1.0 MB)

ARITERM BioComp Boilers 40-300 kW

(1.0 MB)

ARITERM Arimax Bio Boilers 120–3,000 kW

The Ariterm Bio Boiler is a very robust boiler ranging in size from 120 kW to 3,000 kW. The boiler is suited to be used with all the Ariterm burners depending on fuel type available. The fire chamber hatches can be located to suit individual site requirements.

Standard Features

- 120–3,000 kW

- Compatible with all Ariterm burners

- Design pressure 4–10 bar

- Customized fire chamber hatch locations

- Open bottom design

- Ash removal system

Options

- Ceramic insulated ash chamber

- Domestic hot water heat exchanger system

Photos

For more information about ARITERM Arimax Bio Boilers 120–3,000 kW

![]() ARITERM Bio Heating Guide

(1.0 MB)

ARITERM Bio Heating Guide

(1.0 MB)

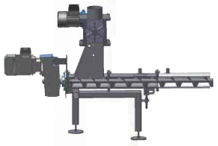

ARITERM PS10 and PS13 Pellet Feeding Systems

PS10 Pellet Feeder (40–400 kW)

In pellet use the pellet screw can be replaced with a PS10 pellet feeder. PS10 is composed of a feeding screw, a cell feeder and a burner screw which are chain steered by one motor. The system allows for more even fuel feeding and also provides one extra back fire protection. PS10 is also equipped with a powder extinguishing system.

PS10 can be combined with BioJet-, HakeJet- and Multi- Jet-burners in power range of 40-400 kW. In Arimatic 500 pellet steering centres the PS10 is operated by a frequency controller.

PS13 Pellet Feeder (500–1,500 kW)

PS13 is composed of a separate cell feeder and a burner screw which are steered by separate motors. PS13 can be combined with BioJet- and MultiJet-burners in power range of 500-1,500 kW. In Arimatic 500/AM1001 pellet steering centres the PS13 is operated by frequency controllers.

For more information about ARITERM PS10 and PS13 Pellet Feeding Systems

![]() ARITERM PS10 and PS13 Pellet Feeding Systems

(0.6 MB)

ARITERM PS10 and PS13 Pellet Feeding Systems

(0.6 MB)

ARITERM Fuel Storage Systems

Models T1, T2, K2 and K4

These modular units come in a variety of sizes and can be added to each other for larger fuel storage systems. The modules come fully assembled which adds to ease of design and installation. The steel rakes move back and forth by a hydraulic unit which is controlled by the central control panel.

Model TPYM

Based on the same principle as the modular units, the TPYM are used in larger system applications with the key components anchored or cast into concrete. All components are delivered loose and must be assembled on site. The base area of the discharge floor can vary between 7.5 and 40m² and up to 200m³. The scope of delivery and configuration of these systems are considered on a project by project basis.

ARITERM Biomass Burners

ARITERM BioJet Burner 60–1,000 kW

The BioJet burner by Ariterm is a water cooled burner and is mainly used for the combustion of wood pellets. The ceramic fire chamber raises the combustion temperature to 1100°C. Separate combustion air fans for primary and secondary air optimize air distribution and efficiency. Automatic ignition is standard. Combustion efficiency exceeds 90% well below the strict current limits.

ARITERM MultiJet Burner 40–1,500 kW

The MultiJet burner by Ariterm has a moving step grate and is ideal for wood chips. The burner efficiently mixes the fuel and facilitates ash removal. The burner comes equipped with automatic ignition and 2 or 4 VFD controlled combustion air fans, depending on the size, for a clean and efficient burn at all power rates. The larger models 700 to 1,500 kW are equipped with two parallel feed screws which enable more even fuel distribution onto the broader grate.

For more information about ARITERM Biomass Burners

![]() ARITERM MultiJet Bio-Burner

(1.4 MB)

ARITERM MultiJet Bio-Burner

(1.4 MB)

ARITERM Residential Boilers

Ariterm 60+ wood fired boilers are modern and efficient self-draught boilers with a very large wood chamber.

Usually this boiler is used for heating detached houses, farm buildings, etc.

Heating is periodic and based on storing energy in a warm water accumulator tank of at least 2000 litres.

Ariterm 60+ wood fired boilers can be supplemented with an Ariterm PX22 pellet burner.

For more information about ARITERM Residential Boilers

![]() ARITERM 60+ Wood Fired Boiler

(0.6 MB)

ARITERM 60+ Wood Fired Boiler

(0.6 MB)

Ekogen Oy

Ventek Energy represents the Ekogen small scale CHP system in North America.

Ekogen Oy offers innovative solutions, systems and services assisting our clients in increasing productivity and decreasing emissions created by energy consumption.

Ekogen Oy develops energy production systems based on ecological values towards energy efficient and enviromentally friendly future. Our values are based on principles of sustainable development and innovations.

Ekogen Small Scale CHP System

The Ekogen Small Scale CHP System output is 100 kW electric power and 300 kW heat, adding up the annual production as high as 800 MWh electricity and respectively heat close to 2500 MWh. The plant is suitable for small industries, housing management companies, green houses and district heating companies — principally to all users which can utilize evenly electricy and heat load.

For more information about Ekogen Small Scale CHP System

![]() Ekogen Small Scale CHP System

(0.6 MB)

Ekogen Small Scale CHP System

(0.6 MB)

Naarva

NAARVA S23 Stroke Harvester

Naarva stroke harvesters are reliable and efficient harvester heads for first thinning.

Naarva S23 is simple and easy to operate lightweight stroke harvester for tractors and 5-8 ton excavators. No electric controllers. All functions are controlled with just grapple open- close-valve. Weight 230 kg. Guillotine cutting 23 cm.

Features

- Felling and delimbing

- Weight 230kg

- Easy installation, no additional hydraulics or electricity.

- Fast guillotine cutting, 23 cm

- Controlled with just grapple open/close- valve

Suitable for

- First thinning

- Making firewood

- Energy wood harvesting

- Integrated harvesting

For more information about the NAARVA S23 Stroke Harvester

![]() Naarva S23 Harvester & firewood processor

Naarva S23 Harvester & firewood processor

![]() Naarva S23 firewood

Naarva S23 firewood

NAARVA E20 Accumulating Energy Wood Head

Naarva E models have been equipped with accumulating grippers that significantly enhance the productivity of small wood harvesting.

The NAARVA E20 Accumulating Energy Wood Head is a light accumulating energy wood head for tractors and 5-8 ton excavators

Features

- Light and efficient

- Excellent loading capabilities

- Effective guillotine cutting, 20–23 cm

- Easy installation, no additional hydraulics or hosing

- Radio control option

Suitable for

- Energy wood harvesting

- Small wood harvesting by accumulation

- Clearing of power lines, road sides and field edges

For more information about the NAARVA E20 Accumulating Energy Wood Head

World Thermal Service

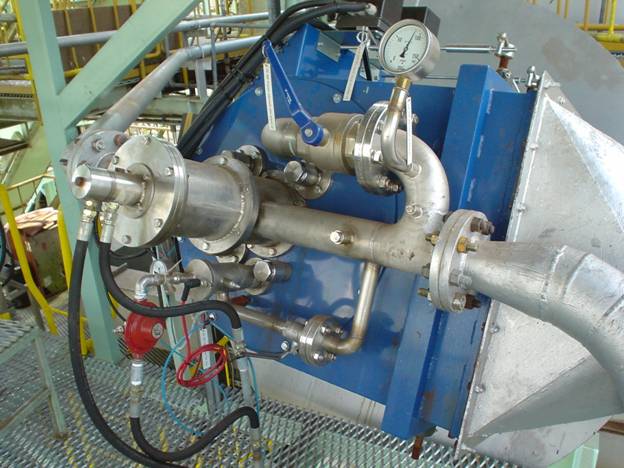

WTS Powder Burner

The WTS Wood Powder Combustion Burner technology and design was undertaken at the nuclear research facility in Stockholm, Sweden. Established in 1989, WTS has over 60 systems installed world wide.

Sizes range from 3 MW to 50 MW and are installed in a variety of industrial settings including, pulp mills, CHP plants, board mills, district heating plants, and electrical generation facilities.

The burner is capable of operating on 100% wood powder with no pilot flame or additional fuel source. It is also capable of burning up to 3 different fuel types, ie waste oil, waste chemicals along with the wood powder at the same time. Turn down ration on the burner is 5:1. Co-firing with coal dust is also possible with the WTS burner system.

Emissions levels on wood powder are below 220 mg / NM3 for NOX and below 150 mg / NM3 for CO.

For more information about WTS Powder Burners

![]() WTS Powder Burners Brochure

(2.6 MB)

WTS Powder Burners Brochure

(2.6 MB)